TS-SEALS

LA PRODUZIONE

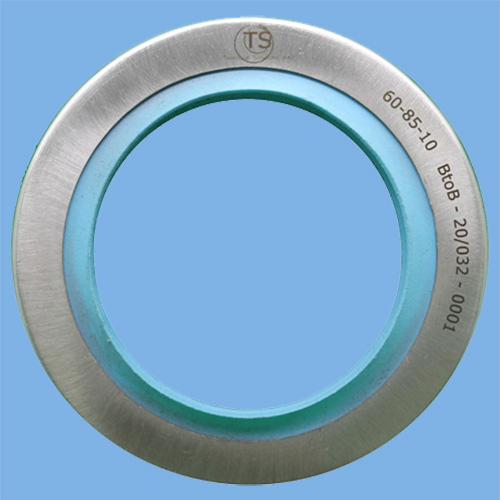

La Technical Solutions srl progetta e produce in Italia, nel suo stabilimento di Desio MB, vicino a Milano, le proprie tenute Radial lip seals TS-Seals, utilizzando materiali esclusivamente di provenienza italiana ed europea.

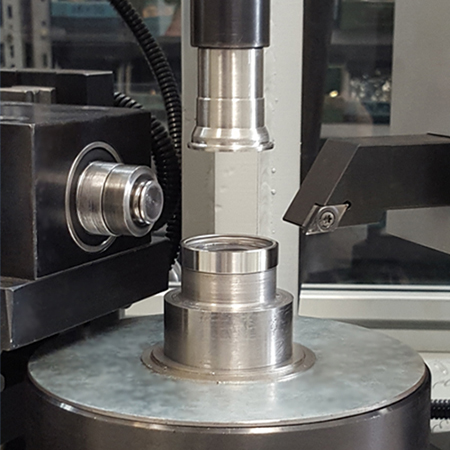

I NOSTRI IMPIANTI

Per realizzare la nostra tenuta TS-Seal, sono necessarie attrezzature che costruiamo direttamente nella nostra azienda.

Gli impianti produttivi di Technical Solutions srl sono studiati per produrre la tenuta radiale TS-Seal fino ad un max diametro esterno di 200 mm.

I VANTAGGI DELLE NOSTRE TENUTE TS-SEALS

✅ Progettazione e produzione in Italia

✅ Materiali esclusivamente italiani ed europei

✅ Velocità di approvvigionamento

✅ Dimensioni standard e su misura

✅ Compatibili con i principali produttori sul mercato

✅ Progetti speciali

✅ Supporto tecnico - service

✅ Consegne rapide in Italia e in Europa

PROFILI - TIPOLOGIE DI RADIAL LIP SEAL TS-SEAL

La Technical Solutions srl realizza le proprie tenute Radial lip seals TS-Seals nei profili standard

✔️ Single lip (Labbro singolo)

✔️ Reverse lip (Labbro esterno)

✔️ Tandem standard lip (Doppio labbro tandem)

✔️ Tandem lip with spin (Doppio labbro tandem con rigatura a spirale (Dx o Sx)

✔️ Back to back (Labbri contrapposti)

✔️ Single lip + durst lip (Labbro singolo + parapolvere)

TS-SEALS DIMENSIONI STANDARD (diametro mm)

SIZE | d1 | d2 | SIZE | d1 | d2 |

|---|---|---|---|---|---|

TS-Seal 8,0 |

8,0 |

17,0 |

TS-Seal 50,0 |

50,0 |

68,0 |

TS-Seal 12,0 | 12,0 | 22,0 | TS-Seal 50,0 | 50,0 | 70,0 |

TS-Seal 12,0 | 12,0 | 28,0 | TS-Seal 50,0 | 50,0 | 72,0 |

TS-Seal 12,7 | 12,7 | 28,5 | TS-Seal 50,0 | 50,0 | 80,0 |

TS-Seal 14,0 | 14,0 | 30,0 | TS-Seal 50,0 | 50,0 | 85,0 |

TS-Seal 15,5 | 15,5 | 28,0 | TS-Seal 55,0 | 55,0 | 70,0 |

TS-Seal 16,0 | 16,0 | 30,0 | TS-Seal 55,0 | 55,0 | 72,0 |

TS-Seal 16,0 | 16,0 | 30,0 | TS-Seal 55,0 | 55,0 | 80,0 |

TS-Seal 17,0 | 17,0 | 35,0 | TS-Seal 55,0 | 55,0 | 90,0 |

TS-Seal 18,0 | 18,0 | 28,0 | TS-Seal 56,0 | 56,0 | 76,0 |

TS-Seal 20,0 | 20,0 | 30,0 | TS-Seal 58,0 | 58,0 | 80,0 |

TS-Seal 20,0 | 20,0 | 32,0 | TS-Seal 60,0 | 60,0 | 75,0 |

TS-Seal 20,0 | 20,0 | 35,0 | TS-Seal 60,0 | 60,0 | 80,0 |

TS-Seal 20,0 | 20,0 | 47,0 | TS-Seal 60,0 | 60,0 | 85,0 |

TS-Seal 22,0 | 22,0 | 35,0 | TS-Seal 63,0 | 63,0 | 80,0 |

TS-Seal 22,0 | 22,0 | 40,0 | TS-Seal 63,5 | 63,5 | 85,0 |

TS-Seal 24,0 | 24,0 | 35,0 | TS-Seal 65,0 | 65,0 | 80,0 |

TS-Seal 25,0 | 25,0 | 35,0 | TS-Seal 65,0 | 65,0 | 84,0 |

TS-Seal 25,0 | 25,0 | 37,0 | TS-Seal 65,0 | 65,0 | 85,0 |

TS-Seal 25,0 | 25,0 | 38,0 | TS-Seal 65,0 | 65,0 | 90,0 |

TS-Seal 25,0 | 25,0 | 40,0 | TS-Seal 65,0 | 65,0 | 95,0 |

TS-Seal 25,0 | 25,0 | 42,0 | TS-Seal 67,0 | 67,0 | 87,0 |

TS-Seal 25,0 | 25,0 | 47,0 | TS-Seal 68,0 | 68,0 | 85,0 |

TS-Seal 28,0 | 28,0 | 40,0 | TS-Seal 68,0 | 68,0 | 90,0 |

TS-Seal 28,0 | 28,0 | 42,0 | TS-Seal 68,0 | 68,0 | 100,0 |

TS-Seal 28,0 | 28,0 | 47,0 | TS-Seal 70,0 | 70,0 | 90,0 |

TS-Seal 28,45 | 28,45 | 41,15 | TS-Seal 70,0 | 70,0 | 95,0 |

TS-Seal 30,0 | 30,0 | 40,0 | TS-Seal 70,0 | 70,0 | 100,0 |

TS-Seal 30,0 | 30,0 | 42,0 | TS-Seal 70,0 | 70,0 | 110,0 |

TS-Seal 30,0 | 30,0 | 45,0 | TS-Seal 70,0 | 70,0 | 125,0 |

TS-Seal 30,0 | 30,0 | 47,0 | TS-Seal 72,0 | 72,0 | 90,0 |

TS-Seal 30,0 | 30,0 | 48,0 | TS-Seal 72,0 | 72,0 | 95,0 |

TS-Seal 30,0 | 30,0 | 50,0 | TS-Seal 73,0 | 73,0 | 92,0 |

TS-Seal 30,0 | 30,0 | 52,0 | TS-Seal 75,0 | 75,0 | 95,0 |

TS-Seal 30,0 | 30,0 | 55,0 | TS-Seal 75,0 | 75,0 | 100,0 |

TS-Seal 32,0 | 32,0 | 47,0 | TS-Seal 75,0 | 75,0 | 110,0 |

TS-Seal 35,0 | 35,0 | 47,0 | TS-Seal 79,5 | 79,5 | 105,0 |

TS-Seal 35,0 | 35,0 | 48,0 | TS-Seal 80,0 | 80,0 | 100,0 |

TS-Seal 35,0 | 35,0 | 50,0 | TS-Seal 85,0 | 85,0 | 110,0 |

TS-Seal 35,0 | 35,0 | 52,0 | TS-Seal 85,0 | 85,0 | 120,0 |

TS-Seal 35,0 | 35,0 | 55,0 | TS-Seal 90,0 | 90,0 | 110,0 |

TS-Seal 35,0 | 35,0 | 62,0 | TS-Seal 90,0 | 90,0 | 120,0 |

TS-Seal 36,0 | 36,0 | 52,0 | TS-Seal 90,0 | 90,0 | 130,0 |

TS-Seal 37,0 | 37,0 | 51,0 | TS-Seal 90,0 | 90,0 | 140,0 |

TS-Seal 38,1 | 38,1 | 57,1 | TS-Seal 95,0 | 95,0 | 120,0 |

TS-Seal 38,1 | 38,1 | 63,5 | TS-Seal 95,0 | 95,0 | 130,0 |

TS-Seal 39,0 | 39,0 | 48,0 | TS-Seal 95,25 | 95,25 | 120,5 |

TS-Seal 40,0 | 40,0 | 32,0 | TS-Seal 95,3 | 95,3 | 108,0 |

TS-Seal 40,0 | 40,0 | 50,0 | TS-Seal 100,0 | 100,0 | 120,0 |

TS-Seal 40,0 | 40,0 | 52,0 | TS-Seal 100,0 | 100,0 | 130,0 |

TS-Seal 40,0 | 40,0 | 55,0 | TS-Seal 108,0 | 108,0 | 130,0 |

TS-Seal 40,0 | 40,0 | 60,0 | TS-Seal 110,0 | 110,0 | 130,0 |

TS-Seal 40,0 | 40,0 | 62,0 | TS-Seal 110,0 | 110,0 | 140,0 |

TS-Seal 40,0 | 40,0 | 65,0 |

TS-Seal 110,0 | 110,0 | 150,0 |

TS-Seal 42,0 | 42,0 | 60,0 |

TS-Seal 112,0 | 112,0 | 132,0 |

TS-Seal 42,0 | 42,0 | 62,0 |

TS-Seal 115,0 | 115,0 | 145,0 |

TS-Seal 42,0 | 42,0 | 80,0 |

TS-Seal 115,0 | 115,0 | 150,0 |

TS-Seal 43,0 | 43,0 | 65,0 |

TS-Seal 120,0 | 120,0 | 150,0 |

TS-Seal 45,0 | 45,0 | 58,0 |

TS-Seal 125,0 | 125,0 | 150,0 |

TS-Seal 45,0 | 45,0 | 60,0 |

TS-Seal 130,0 | 130,0 | 160,0 |

TS-Seal 45,0 | 45,0 | 62,0 |

TS-Seal 133,35 | 133,35 | 152,4 |

TS-Seal 45,0 | 45,0 | 65,0 |

TS-Seal 140,0 | 140,0 | 170,0 |

TS-Seal 48,0 | 48,0 | 65,0 |

TS-Seal 145,0 | 145,0 | 175,0 |

TS-Seal 49,0 | 49,0 | 70,0 |

TS-Seal 145,0 | 145,0 | 180,0 |

TS-Seal 50,0 | 50,0 | 62,0 |

TS-Seal 150,0 | 150,0 | 180,0 |

TS-Seal 50,0 | 50,0 | 65,0 |

TS-Seal 152,0 | 152,0 | 180,0 |

MATERIALI

PARTI METALLICHE:

✔️AISI 316L - Carbon Steel - Alloy C276

LIP:

✔️PTFE caricati - PU - ...

ELASTOMERO:

✔️NBR - FKM - VQM - EPDM - ...

CONDIZIONI OPERATIVE

Pressione:

✔️ Standard seal 10Bar

✔️ Special seal 25Bar

Temperatura: -90/+250°C

Velocità: fino a 40 m/sec.

APPLICAZIONI

✅ Pompe

✅ Centrifughe

✅ Mixer

✅ Compressori a vite

✅ Agitatori

✅ Separatori

✅ Dosatori

✅ Turbine

SUPERFICIE DI TENUTA

Durezza superficiale:

✅ Fino a 1,5 bar - min 45 HRC

✅ Oltre 1,5 bar - min 60 HRC

Rugosità superficiale: 0,2 Ra xx 0,4 Ra